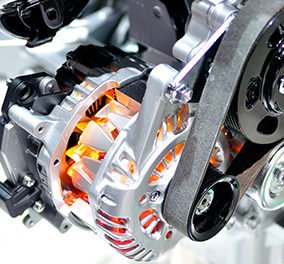

The tension belt is a pulley-mounted system that is loaded on a spring or pivot point mechanism. This unit is known as the Accessory Belt Drive System (ABDS). It supplies tension to engine belts. When functioning the entire system properly keeps the vehicle running smoothly, but if any one part of the system fails, it could affect the alternator. Subsequently, the battery, the engine, and the car could break down.

The belt tension must have the proper amount of tension to keep the Accessory Belt Drive System from failing. The belt system transfers torque to run the accessories. When problems occur, many tend to believe that it is the belt that is the issue. In actuality, belt tension is often the number one problem when it comes to the accessory system failures. Anything that disrupts the process of the system can cause the entire unit to fail.

The tensioner can pull over a billion times and last for more than 100,000 miles, but if it malfunctions, it can cause the belt to slip which can result in a variety of mechanical issues. Belt slippage occurs when there is too much torque for the surface, and there is not enough friction available to keep the belt on the pulley. There are many reasons why belts slip.

Reasons Belt Tension Fails

Belt Slip – Tension ensures that there is a balance to power the accessory system. When the tension malfunctions, the belt can slip, causing noise and heat.

Belt Misalignment – As the system processes, all of the pulleys should be aligned. Tensioners can become worn which stresses the pivot bushing. The tensioners arm moves out of alignment, causing the belt to move upward. Subsequently, the pulley becomes noisy after it is damaged. The accessory system can only take one degree of misalignment before the belt and tension fail.

Tension Damper – The damping mechanism controls vibrations and power fluctuations. When it begins to wear out, it limits the tension arm movement. The belt will begin to slap the next accessory, putting unbearable stress on the system causing it to fail.

Belt/Pulley – Belts and pulleys mate, or fit tightly together to keep the entire system running smoothly. With normal wear and tear, the belt can lose material. If it loses more than 5%, the belt won’t mate properly with the pulley, and it will lose traction. Water won’t escape properly and can weed between the belt and the pulley causing the belt to hydroplane.

Belt Slip and the Alternator

When the ABDS works correctly, then all other parts will work in conjunction together without a hitch. As the belt wears and begins to shift or slip, you’ll hear grinding, slapping, or squeaking noises. When the belt is not functioning properly, a high output alternator can receive undue stress. Alternators are extremely susceptible to excessive heat or vibrations. A driver may notice their “Check Engine” light and need to have the vehicle diagnosed.

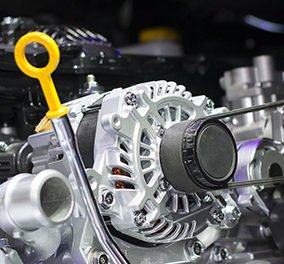

Replacing the Alternator

You should consider replacing the alternator when you replace the belt. You can purchase a professional high output alternator at any auto parts store, but be wary of an aftermarket replacement alternator. They can have a lower wattage output and sound louder when the vehicle is running. If you do decide to get an inexpensive aftermarket alternator, make sure it is an OEM (Original Equipment Manufacturer) part.

Alternator Tech Tips

Alternator Replacement Made Easy

How to replace your vehicle’s alternator on your own rather than paying a professional to handle it.

Battery Tech Tips

Do You Need A Jump Pack?

A battery jump pack is something you might carry for years and never need, but the one time you do need it, you will appreciate having it. A battery jump pack is essentially a battery charger, or a device to start your car when your battery is dead. People still carry...