A vehicle comes with a stock alternator from the factory to meet the basic electrical needs of a vehicle. Even though the vehicle comes with a stock alternator that can fulfill the basic needs of the car such as supplying power for the lights and sound system. However, since the vehicles today are highly upgraded a great alternative to a standard alternator for supplying amps is a high-output alternator.

A high-output alternator is a perfect way to upgrade modern vehicles. A modern vehicle is different from a traditional vehicle since it can require a higher electrical supply for, power windows, modern seats with heating and cooling systems, power gates, ignition systems, compressors, navigation systems, and more. A high-output alternator provides higher amperage output to a vehicle, improving its performance. This article discusses the different types of high-output alternators, their functions, how they work, and how to prevent them from going bad. To find out more about high-output alternators please read below:

How Does an Alternator Work

A high-output alternator is generally used to increase the amperage within the electrical system. When an alternator is not turning quickly, the output could be reduced hence not keeping up with the demands of a charging system. In such a case battery has to make up for providing the amps, that’s why the reserve of the battery is considered like a deposit account that saves power. The amps stored in a battery’s reserve capacity then provide the amps when the electrical load exceeds the charging system output. However, this could affect the power of the battery negatively and put pressure on the battery. Therefore, a high-output alternator is recommended to save the battery’s power and provide the required electrical output and amps to a vehicle. When a high-output alternator is used, amps are supplied back to the battery when the vehicle is used, and with a high-output alternator charging systems are able to generate more amps and supply the vehicle with the amps required to keep the vehicle running.

A high-output alternator functions by providing the required amps. A high-output alternator can be used in case of alternator failure. Alternators run on the basis of load on the charging system, so the higher the amps required, the more the pressure on the charging system and the higher the operating temperature of an alternator would be. A high-output alternator is recommended in case additional accessories are added to a vehicle because the stock alternator might not be able to handle the demand of higher amp and voltage that are required to run additional accessories.

In order to find out more about the types of high-output alternators please read below:

Types of High-Output Alternators

A basic alternator that is traditionally installed in vehicles provides power for basic functions such as ignition, starting the engine, audio, lights etc. However, traditional alternators can only run for a few minutes under extreme load and can be damaged due to overheating. In order to avoid alternator damage due to overheating, high-output alternators are designed. There are different types of high-output alternators depending on the type of car, power requirements, and the functions of the car. The three basic types of high-output alternators are alternators required for audio, alternators required for running applications, and high-output alternators for all functions.

Special Designed Alternators

Specialty-designed alternators are designed to provide power to all applications and systems of a car without being overheated. Companies such as Leece-Neville and Neihoff design high-output alternators that can supply amps for all functions of a car without exceeding the temperature limit and being damaged. Choosing a specialty-designed alternator depends on the type of car you have and the functions you want to perform. Therefore, different companies design different types of specialty-designed alternators according to the exact amps required by a car.

High Output Alternator Required for Audio

Based on our needs for sound systems the requirement for output changes therefore special high-output alternators are designed to run different audio systems in a car. As a car’s sound system is upgraded and audio output increases the requirement for energy to run the sound output also increases. For example, typically 16 amps are required to run around 100 watts of audio, so if a vehicle has a 100-watt amplifier the traditional alternator can produce the electrical energy of 16 amps, but if a vehicle has an amplifier of more than 100 watts then a high output alternator will be required to run the function.

High Output Alternator Required for Applications

Some vehicles are upgraded to run more applications e.g. vehicles that don’t come with electric doors and windows would require a high-output alternator if the windows are upgraded to electric from manual. If the lights of a car are upgraded and additional lights are added i.e. emergency lights for police cars then a high-output alternator would be required.

Thus, high-output alternators designed to run applications are designed to run any applications that require more amperage than the stock alternator can provide. Dynamo generators and OEM alternators are two examples of alternators designed to provide the additional electric power required by a vehicle.

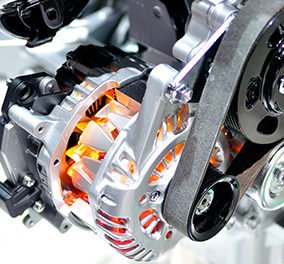

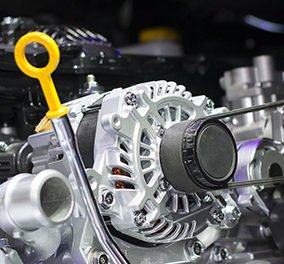

What are the parts of an alternator and their functions?

High-output alternators are designed to achieve high-output functions, therefore, they are designed with heavy-duty diodes in order to produce and handle large currents and heat. The different parts of a high-output alternator would be its diodes, wires for producing electric current, and heat-resistant parts in order to increase their durability. In addition, some high-output alternators also contain chrome-plated compartments in order to increase their resistance to harsh conditions.

An alternator needs to have a wiring harness to handle the alternator output and different amp alternators to generate high electric output.

How does an alternator go bad?

An alternator goes bad when it’s used in extreme conditions and needs to produce higher amperage than it can handle. In order to prevent an alternator failure, it is important to know the output capacity of an alternator and upgrade the alternator when the amps requirement of the vehicle increases due to up-gradation. The picture in the above section shows the different parts of alternators, the cooling fan, finger pole rotors, slip rings, and bearings. An alternator goes bad if one of the parts stops working.

The most common instance of an alternator going bad is bearing failure because of accumulation of dirt in the alternator which halts the function of an alternator and causes damage because of overheating.

Conclusion

A high-output alternator should be used if you want to upgrade your vehicle and the upgrade requires higher electrical output from the vehicle. The type of alternator you should purchase depends on the type of upgrade and the function an alternator is required to perform. It is important to check an alternator regularly in order to assess whether it’s functioning properly or if it needs to be changed. Generally, loud noises from a vehicle, dim lights, or sound system not functioning properly can be linked to an alternator failure, because these things happen when an alternator stops functioning properly. Therefore, check regularly if the alternator is performing its duties properly and change the alternator if it’s not functioning properly.

It’s good to know that stock alternators might not be able to handle increased loads if you add more electrical systems to the car. My father gave me his old car when he stopped driving earlier this year and I want to upgrade a couple of systems in the car. I’ll have to look at what load I expect to put on the vehicle and make sure I get parts that can handle it.

Hi please help me, I have a 2016 Toyota Fortuner I use for 4×4 outdoor camping fitted with duel battery system for camp fridge, camera, cell and other two-way radio charging, but the alternator does not seem to charge the second battery sufficiently.

So being a Smart alternator system can i replace it with a higher ampere rating alternator. The point is i do not use this vehicle for camping alone but 70% road use for work, would the higher ampere unit damage the car system or will the regulator take care of the additional power