What goes in must go out. A performance engine inhales more gas and air to make more horsepower. That excess must get out and small stock exhaust isn’t going to cut it. In fact, the horsepower gain you got with that better intake and fuel system may be negated by an exhaust that is too small or too restrictive. The hardest part of replacing the exhaust is determining the size you need. Yes, an exhaust that is too big could also negatively affect horsepower.

Performance Exhaust System Replacement

Weather and inaction often make the nuts and bolts on an exhaust system rust. Before you get started removing pieces, give all of the connectors a good spray of WD-40 or PB Blaster. Let them soak for about 10 minutes. Support the exhaust with a transmission jack and working from the back, start removing sections. As you move toward the front of the vehicle, move the jack or other support to keep the rest of the exhaust from pulling down on the exhaust manifold or headers. If you have a nut or bolt that won’t loosen, give it another shot of the anti-rust/cleaner. If it still won’t come off, you’ll have to cut it off or take out two sections at the same time. If you are not replacing the entire exhaust, you could cut the section out and weld in a new piece or replace the sections that do not come unbolted. One is a matter of time and the other is a matter of more money.

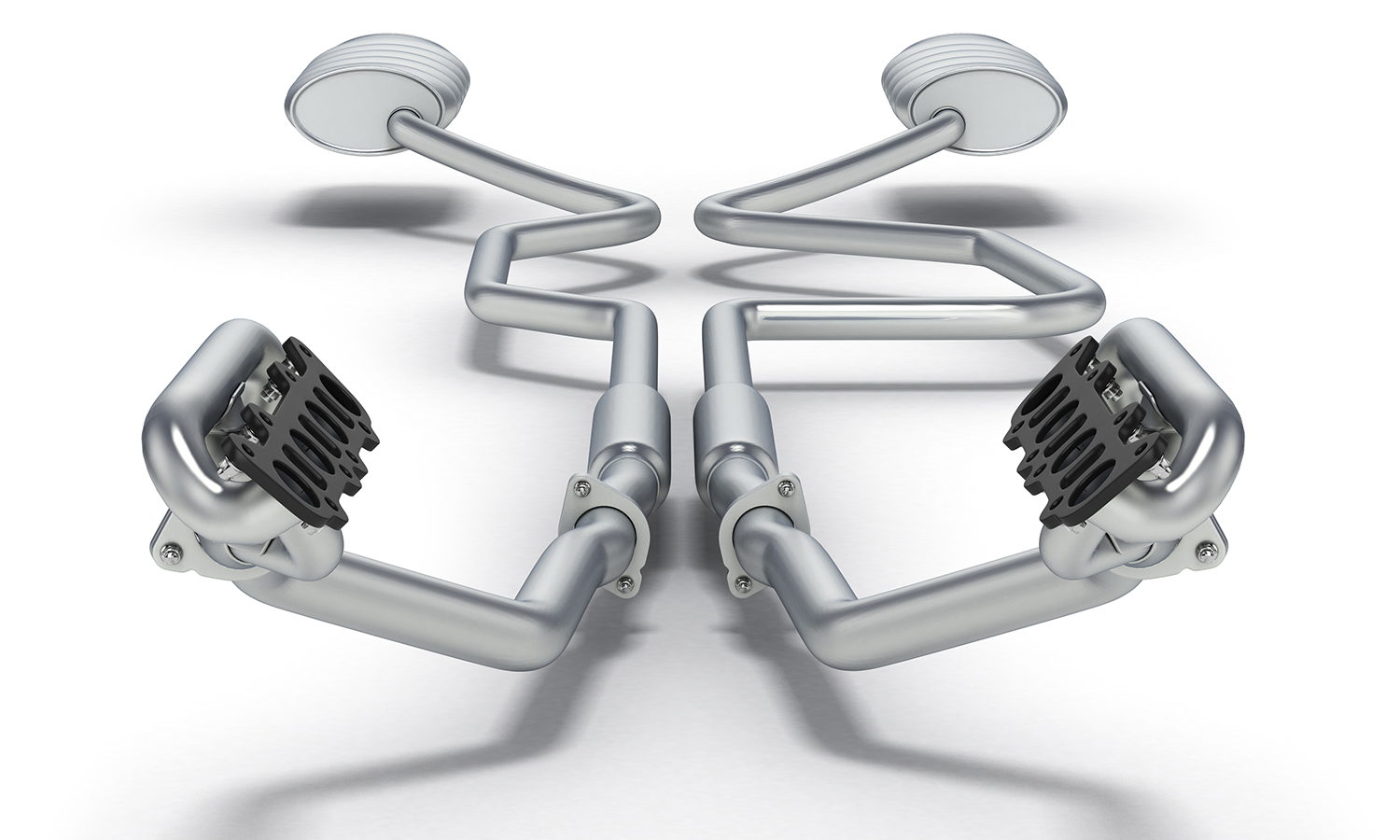

Removing and Installing the Exhaust Manifolds/Headers

If you are replacing the exhaust manifold with high-performance headers, it is advisable to disconnect the negative battery cable because the manifold is usually very close to the starter. Instead of taking a chance that a wrench or ratchet hits the hot wire on the starter, it’s easier to just disconnect the power. Before you remove the manifolds, make sure everything is out of the way. You may have to remove the oil or transmission dipstick. If any wire loom brackets are bolted to the engine with the exhaust bolts, carefully remove the wiring harness from the brackets and set it aside. If the vehicle has plug wires and plugs, you may have to remove the wires and plugs. Before you remove the wires, number each wire so that you put it back on the same cylinder or you’ll be spending time looking up the firing order when it’s time to put it back together. Sometimes, because of the angle of the exhaust manifold or header, one or more spark plugs may need to be removed. In removing the manifolds, pay attention to where each of the manifolds hangs up – it could be on a plug. Just remove the plug that is in the way. When you install the high-performance exhaust system, start from the headers and work back. In most cases, you do not need a gasket-maker to hold the gaskets on. However, if you do have problems lining up the gaskets, use a thin layer of high-temperature gasket maker – just enough to make them stick to the exhaust ports. As you are bolting the headers up, be sure the gaskets are straight before you torque the exhaust bolts. As you go through the rest of the exhaust, always make sure the new gaskets are lined up before torquing the bolts.